Why Municipal Corporations Prefer FRP Products for Urban Infrastructure

Municipal planners in India are increasingly turning to FRP products for urban infrastructure. This composite material is lightweight yet strong and often described as “the material for the future.”

Some officials even consider FRP as a good prospect in renewable energy, infrastructure and transport. This is because it can resist rust and rot, and cuts maintenance needs in harsh climates.

Let’s move further in the blog to learn more about why FRP is being preferred for urban infrastructure by municipal corporations.

The Role of FRP in Modern Cities

Modern cities need infrastructure that remains strong in harsh weather conditions, heavy usage, and different environmental challenges. FRP products for urban infrastructure have a high strength-to-weight ratio, corrosion resistance, and design flexibility. They serve all these challenges while maintaining aesthetic appeal and functionality.

Major metropolitan cities like Mumbai, Pune, and Surat have already initiated the deployment of FRP infrastructure on a large scale. Municipal corporations of Greater Mumbai have already implemented FRP tanks for water treatment facilities.

Moreover, the Smart Cities Mission across India has further accelerated FRP applications for urban development. Cities like Pune are using RFID-enabled FRP manhole covers for real-time monitoring and predictive maintenance.

These installations show how FRP technology is not just replacing traditional materials but also enabling new capabilities for urban infrastructure management.

Why Municipal Corporations Prefer FRP Products

FRP products for municipalities are superior to traditional materials as they directly impact operational efficiency and budget management. They are highly preferable products due to the following reasons.

1. Durability and Weather Resistance

Products like cast iron and concrete rust and crack in a harsh urban environment. However, FRP products for urban infrastructure maintain structural integrity across extreme temperatures and UV and chemical exposure. They show exceptional resistance to corrosion, even in coastal areas where salt exposure rapidly ruins metal alternatives. As a result, they remain functional and aesthetically pleasing for decades without requiring frequent repairs or replacements.

2. Lightweight and Easy Installation

FRP applications in urban development significantly reduce installation complexity and costs. They weigh up to 70% less than cast iron alternatives while maintaining superior strength. This eliminates the need for heavy lifting equipment and reduces installation time by up to 50%. Their lightweight nature also reduces labour costs and minimises disruption to urban traffic during installation.

3. Cost-Effective

The initial cost of FRP production is slightly higher. However, FRP products for municipalities deliver substantial long-term savings through reduced maintenance, extended lifespan, and lower operational costs. Since they do not have scrap value, there are no theft-related replacement costs. Furthermore, transportation costs are also up to 30% lower due to lightweight and installation efficiency. Municipal Corporation states that they tend to save a lot over a 10-year period when switching from traditional materials to FRP solutions.

4. Eco-Friendly and Sustainable

FRP products for urban infrastructure support sustainability goals through energy-efficient manufacturing, reduced carbon footprint during transportation, and recyclable end-of-life disposal. The production process generates fewer CO2 emissions compared to steel manufacturing.

FRP remains the same over a long time, which reduces replacement. They minimise waste generation and resource consumption over the product lifecycle. Many FRP products can be repurposed or recycled at the end of their service life, which supports circular economy principles.

Key FRP Products Used By Municipal Corporations

Municipal corporations deploy various FRP products for urban infrastructure. They offer unique advantages for modern city management.

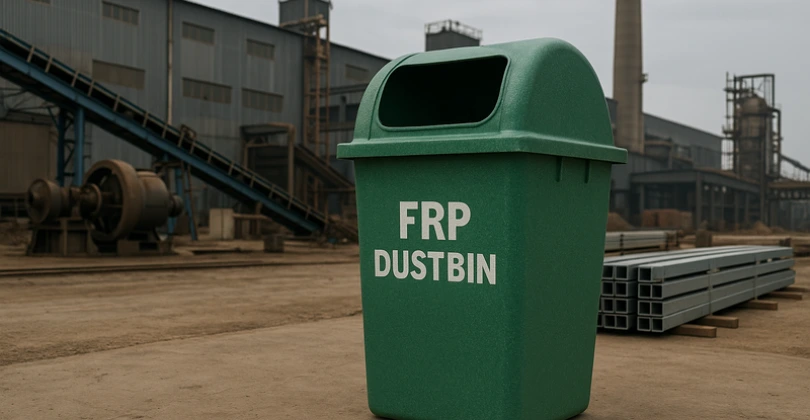

1. FRP Dustbins

FRP dustbins have become essential components of urban waste management systems. These containers resist harsh weather, UV damage, and chemical exposure while maintaining hygienic conditions. Their lightweight feature facilitates efficient waste collection, with sanitation workers reporting faster collection times.

FRP dustbins are also available in multiple compartments for waste segregation, which supports sustainable waste management practices. Municipal corporations particularly value their vandal-resistant properties and customisable designs that improve urban aesthetics.

2. FRP Portable Toilets

FRP portable toilets provide essential sanitation infrastructure for construction sites, events, and temporary installations. These units offer superior durability while maintaining hygiene through non-porous surfaces. Municipal corporations like their modular designs as they allow for customisation based on specific requirements. Moreover, their lightweight construction enables easy relocation and installation without heavy machinery.

3. FRP Cabins

Security and worksite cabins made of FRP are prefabricated and modular. They are corrosion-free and usually pre-assembled offsite, so they can be placed in a day. FRP cabins do not need painting and have built-in insulation, windows, and wiring. Most importantly, they are light enough for crane installation and tough enough to hold up in the sun and rain. They last for years without any repairs.

4. FRP Benches

FRP parks and street benches are extremely common today. They are weatherproof and do not require any maintenance. Plus, they can be customised in colour or even wood-like finishes. They do not warp, rust, or resist graffiti, unlike wood or metal benches.

5. FRP Planters

FRP materials are also used in making large planters for trees and shrubs. These planters are light, so they can be moved by hand or machine. However, they are strong enough to hold soil and plants. FRP planters also do not crack in summer heat or mildew in wet weather. They come in many shapes and styles, and like benches, they require no painting. Municipalities use FRP planters to line plazas and parks with greenery.

6. FRP Tanks

FRP tanks are used in place of steel or concrete for water and chemical storage. Underground FRP water tanks are corrosion-resistant and have a high strength-to-weight ratio. FRP supplier in India states that FRP tanks can handle chemicals without degradation. This makes them an ideal long-term investment for municipal water systems or treatment plants.

Case Studies

Several Indian cities have successfully implemented FRP infrastructure solutions. One vivid example is Tata Steel’s COVID-19 hospital project. In 2020, Tata Steel collaborated on a 500-bed field hospital in Kasaragod, Kerala. Instead of building all-steel cabins, they employed FRP sandwich panels for the quarantine/isolation blocks. The result was a setup that could be mass-produced quickly yet remained durable. FRP panels give a more durable material than traditional options. This case showed how FRP can speed up emergency infrastructure with high-quality results.

In urban spaces, municipalities have similarly adopted FRP products. Many Indian smart city parks now feature FRP benches and planters instead of wood or concrete. These FRP street fixtures stay intact through monsoons and heat with little upkeep.

In Mumbai, Creative Fibrotech even installed FRP compost bins in a civic ward to aid cleanliness. Overall, city planners in India are piloting FRP in everything from public toilets to metro stations, which confirms FRP’s utility in real projects.

Why Creative Fibrotech is the Preferred FRP Partner for Municipalities

Creative Fibrotech has built a strong reputation as a one-stop FRP supplier in India. With 12+ years of experience and over 50,000 projects delivered, they specialise in tailor-made FRP solutions for India’s cities. Their FRP tanks are described as the best as they meet the stringent needs of municipal water storage.

Furthermore, Creative Fibrotech offers a complete range of city-relevant products that are engineered for durability in Indian conditions. They also hold key ISO certifications and support projects from design through deployment. Municipal corporations trust Creative Fibrotech as it delivers sturdy and maintenance-free FRP products for urban infrastructure.