5 Main Types of FRP Composites and Their Uses

Have you ever wondered what makes modern planes lighter, bridges stronger, and sports cars faster? The answer is Fiber-Reinforced Polymer (FRP) composites.

They are materials created by mixing strong fibers, like carbon or glass, with a polymer matrix. When traditional materials, like steel, wood, or aluminum, cannot do their job, FRP is considered.

There are several types of FRP, with each one having its own strength, performance, and use cases.

Move further in the blog to learn about these FRP materials types in detail.

What are FRP Composites?

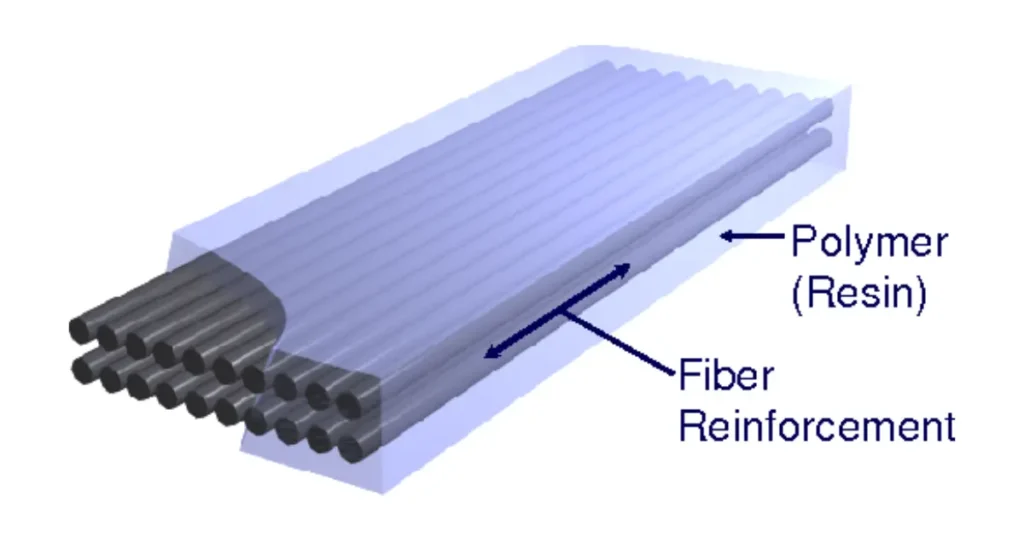

Fiber-reinforced polymer (FRP) composites are materials made by mixing strong fibers, like glass, carbon, or aramid, into a polymer matrix.

The fibers in FRPs give strength, whereas the plastic holds everything together. Unlike traditional material, which is the same in all directions, FRP is anisotropic. Its strength depends on fiber orientation.

Moreover, their lightweight and corrosion-resistant features make different types of fiber-reinforced plastic widely common in the construction, aerospace, and marine sectors.

However, not all types of FRP composites are equal. Their performance can differ in terms of temperature, environment, and how fast they are loaded.

Main Types of FRP Material

The types of FRP differ by the fiber used. Let us look at each one of them and learn what makes them special:

1. Glass Fiber Reinforced Polymer (GFRP)

Glass Fiber Reinforced Polymer (GFRP) or fiberglass is a material created by mixing glass fibers with plastic resin. This is one of the popular fiber-reinforced polymer types. Engineers use different glass types (E-glass, S-glass) and resins to make GFRP perfect for specific jobs.

Properties: GFRP is super strong and lightweight. It lasts long and does not rust. This FRP also blocks electricity and does not let heat pass through easily.

Uses: This FRP is widely used in different industries, like construction, aerospace, automotive, and marine.

2. Carbon Fiber Reinforced Polymer (CFRP)

Carbon Fiber Reinforced Polymer, or CFRP, is made of two parts: carbon fibers and a polymer (usually epoxy). The carbon fibers are thin and strong strands made by heating special materials. The polymer, on the other hand, holds these fibers together and protects them from damage.

Properties: Among different types of FRP, CFRP has a strength-to-weight ratio. It resists pulling, repeated stress, and corrosion.

Uses: Since CFRP is lightweight, it is widely used in planes, cars, wind turbines, buildings, boats, and sports gear.

3. Aramid Fiber Reinforced Polymer (AFRP)

Aramid Fiber Reinforced Polymer (AFRP) is another one of the most popular types of FRP composites. It uses aramid fibers (like Kevlar) mixed with plastic resin (like epoxy or polyester). The aramid fibers provide strength, while the plastic holds everything together and helps spread out forces.

Properties: AFRP is good at absorbing impacts. It does not break easily when damaged and resists many chemicals.

Uses: AFRP is used in bulletproof vests, airplane parts, building materials, sports equipment like tennis racquets, and industrial items, like ropes and protective clothing.

4. Basalt Fiber Reinforced Polymer (BFRP)

Basalt Fiber Reinforced Polymer (BFRP) is made by combining basalt fibers with plastic resin. The basalt fibers come from volcanic rock that is melted at high temperatures (about 1400 °C).

Properties: BFRP is strong, can resist chemicals, and can handle high heat. It lasts long even when wet.

Uses: This FRP composite is used in energy infrastructure, MRI and RF environments, and sustainable buildings.

5. Hybrid FRP Composites

Hybrid FRP mixes different types of FRP material in one product. For example, they combine carbon fibers for strength with glass fibers to save money. They can also use natural fibers inside with synthetic fibers outside.

Properties: Hybrid FRP composites are stronger, lighter, and more durable. They improve design flexibility, resist damage better, and are more affordable.

Uses: They are widely used in several industries. It includes automotive, construction, sports equipment, and marine industries.

How to Choose the Right FRP Type for Your Needs

Different types of FRP offer different strengths. So, here is what you need to look for while choosing the right FRP:

- Pick an FRP that can handle harsh chemicals if needed.

- Make sure it can support the expected weight and stress.

- Consider heat, cold, UV rays, and humidity while picking the FRP.

- Some FRP material types insulate, while others conduct. Keep that in mind as well.

- Choose the right profile for strength and fit.

- Balance quality with your budget.

Conclusion

When the demand is for strength, flexibility, and durability, choosing the right types of FRP can make all the difference. It boosts performance while cutting down weight and maintenance.

But remember, there is no one-size-fits-all. The best choice depends on your needs, environment, and budget. That is why working with an expert team matters.

At Creative Fibrotech, we use the right types of fiber-reinforced plastic to build custom projects.

So, what are you waiting for? Get your custom order now.